A circular saw is a very versatile tool that you need to have in your workshop. For you to achieve smooth and precise cuts, you should have the best circular saw blades.

Circular saw blades vary in terms of quality from one brand to another. It is important to know how to pick the right one so that you can enjoy the best cutting experience.

Selecting the right circular involves a lot of things. Some blades are used to cut particular materials and circular saw blade sizes also vary.

I created this detailed guide and review to provide you with relevant information that will help you pick a suitable circular saw blade.

So, if you need the best circular saw blades for plywood or any other material, I’m sure you will get the right one here.

TOP 3 RECOMMENDED BEST CIRCULAR SAW BLADES

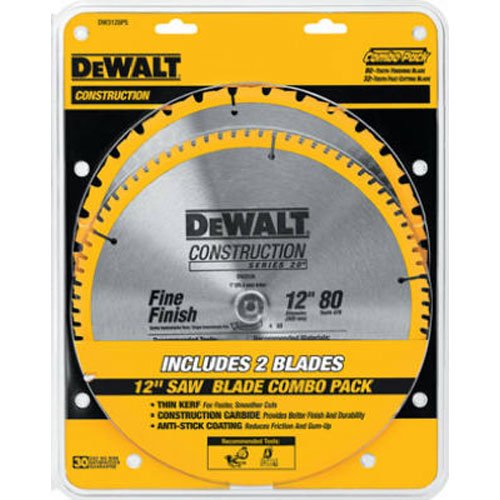

#1 Dewalt Accessories DW3128P5 12-Inch

I would recommend the Dewalt Accessories DW3128P5 12-Inch if you want an affordable option. You will enjoy two blades at a very pocket-friendly price and they work well when it comes to cutting materials.

- ACCURATE CUTS: DEWALT DW3128P5 80-Tooth 12 Inches Crosscutting Tungsten Carbide Miter Saw Blade 2 Pack, helps you make quick, smooth, and accurate cuts

- TUNGSTEN CARBIDE: Tougher tungsten carbide stays sharper longer

- THIN KERF: Thin kerf for fast and smooth cutting action

- BLADE VERSATILITY: 1 blade with 80 teeth and 1 with 32 teeth for added versatility

- REDUCED VIBRATION: Includes carrying bag for easy portability and storage

- WARRANTY: Backed by a 3-year limited warranty

#2 Oshlun SBF-080048 8-Inch 48

If you are looking for a durable circular saw blade for metal cutting, I would recommend the Oshlun SBF-080048 8-Inch. Not only does it come at an affordable price but it also lasts 30 times longer than other abrasive blades. It also offers 5-10 times faster cuts as compared to other blades.

- Fits: Milwaukee and 8-1/4-Inch Saws

- Max RPM: 5,800

- Professional Grade C-6 Carbide

- Laser Cut Expansion Slots

- Triple Chip Tooth Gr

#3 Irwin Tools Metal-Cutting Saw Blade

If you are looking for a durable circular saw blade for metal cutting, I would recommend the Oshlun SBF-080048 8-Inch. Not only does it come at an affordable price but it also lasts 30 times longer than other abrasive blades. It also offers 5-10 times faster cuts as compared to other blades.

- Laser cut blade

- Anti-vibration vents prevent wobble for straighter, truer cuts

- Metal cutting grade carbide teeth stay sharp for long-lasting durability

- Anti-kickback tooth shoulder for safer cutting

- Ideal for cutting thin st

WHY DID I CHOOSE TO REVIEW BEST CIRCULAR SAW BLADES?

One of the main problems that many woodworkers face is getting the right blade for their tools. And as you know, having the wrong blades on your circular saw will affect your work negatively. Not only will you get poor cutting results but also you can end up damaging your tool.

I aim to provide buyers with helpful information so that they can get the best products on the market today. I did extensive research on the market to provide you with circular saw blades explained. After checking my recommended models, I believe it will be easy for you to select the right tool that meets your needs.

WHY SHOULD YOU INVEST ON IDEAL CIRCULAR SAW BLADES?

Investing in the right circular saw blades for wood cutting will help you get accurate and smooth cuts on different materials. And because there are many saw blades on the market today, it can be tough to know which one is suitable for your saw.

I have provided you with a circular saw guide and reviews to make your buying easy. There are many benefits that you will get from having the right blade on your tool. It is easy for the blade to strike through the material and provide you with straight and precise cuts.

The right circular saw blades are also ideal if you want to achieve angle cuts when you are cutting through deep concrete. So, if you need to get a great cutting performance when you are dealing with your projects, invest in the best circular saw blade for ripping hardwood or other materials to match your requirements.

THE 7 TOP RATED BEST CIRCULAR SAW BLADES FOR PLYWOOD ON MARKET

I sampled different circular saw blades on the market today. This will help you narrow down your options when it comes to picking the right one. The following are my top picks that you can consider buying for your circular saw.

#1 Dewalt Accessories DW3128P5 12-Inch Saw Blade Pack

Dewalt is a renowned brand when it comes to power tools and other accessories. This tungsten carbide circular saw blade is ideal to cut through different materials. The blade features a thin kerf to provide you with fast and smooth cutting.

It has a computer balanced plate that reduces vibrations when you are cutting so you will end up with smooth cuts. This circular saw blade is designed with a unique wedge shoulder design and this ensures there is more steel behind every tip.

As a result, you can enjoy accurate cuts and durable use. This blade is ideal for cutting different materials like hardwood, softwood, chipboard, and plywood among others. It features an anti-stick coating to reduce friction as well as gum up.

SPECIFICATIONS

- Size: Standard

- Material: Carbide

- Weight: 4.8 pounds

- Dimension: 17 x 13.6 x 0.6 inches

PROS

- Tungsten blade that remains sharper

- Provides smooth and accurate cuts

- It can cut different type of materials

- Minimal material wastage when cutting

- Two amazing blades at an affordable price

CONS

- The blades are poor in finish work

BOTTOM LINE

This is a nice blade that stays sharper for longer. It provides you with accurate and smooth cuts because it has a thin kerf. You will also enjoy blade versatility since the blade has 80 teeth and the other one that has 32 teeth to increase the versatility. This quality blade is designed to last for many years and it is backed up by a three-year limited warranty.

- ACCURATE CUTS: DEWALT DW3128P5 80-Tooth 12 Inches Crosscutting Tungsten Carbide Miter Saw Blade 2 Pack, helps you make quick, smooth, and accurate cuts

- TUNGSTEN CARBIDE: Tougher tungsten carbide stays sharper longer

- THIN KERF: Thin kerf for fast and smooth cutting action

- BLADE VERSATILITY: 1 blade with 80 teeth and 1 with 32 teeth for added versatility

- REDUCED VIBRATION: Includes carrying bag for easy portability and storage

- WARRANTY: Backed by a 3-year limited warra

#2 Freud 7-1/4″ X 60T Thin Kerf Ultimate Plywood & Melamine Blade

This is a heavy-duty saw blade that offers precise cutting performance. You can enjoy chip-free finishes when you are handling different materials like melamine countertops, veneered plywood, and hardwood molding.

The blade has 60 teeth and it is equipped with TiCo high-density carbide tips that reduce heat buildup and friction when you are cutting. Additionally, the thin kerf ensures that you get accurate cuts all the time. The blade is perfectly balanced and has anti-vibration slots to minimize chatter and offers you a cleaner finish.

This extends the blade life and minimizes noise when you are working. The blade is flat, stable, and remains true even after using it for a long time. It can withstand tough use because it has a Perma-Shield, which is a nonstick surface that reduces friction and offers thermal insulation to protect your tool and the working surface.

SPECIFICATIONS

- Size: 7-1/4″Weight: 12 ounces

- Dimension: 7.5 x 7.5 x 0.5 inches

- Material: Carbide

- Cutting Diameter: 7.25 inches

PROS

- Features heavy-duty plate that has laser slots

- The blade provides accurate cuts

- Heat and impact resistant for a durable use

- Has an effective coating to prevent corrosion

- Produces less noise during operation

CONS

- Complaints of bent tooth

- The blade warps with ease

BOTTOM LINE

This is an ideal blade that is suitable for cutting plywood, laminate, and crosscutting hardwood. The blade features a strong construction meaning that it will serve you for many years. It is also designed with a large number of teeth that help you achieve splinter-free finishes even when you are cutting hard materials like laminate. This blade also handles thicker and thinner materials perfectly.

- 7-1/4 Blade Diameter, 60 Teeth, Hi-ATB Grind, 5/8 Arbor, .079 Kerf, 2° Hook Angle

- Premium TiCo HI-Density Carbide Crosscutting Blend for Maximum Performance

- High Alternate Top Bevel (HiATB)Tooth Design produces splinter-free cuts

- Laser-Cut Anti-Vibration Slots drastically reduce vibration and sideways movement in the cut extending blade life and giving a crisp, splinter-free flawless finish

- Perma-Shield Non-Stick Coating reduces blade drag, protects the blade from corrosion and pitch build-

#3 LENOX Tools 8-Inch Circular Saw Blade, Steel-Cutting

When picking a circular saw blade, it is important to consider the type of blade that you want. For instance, do you want a blade that you can re-sharpen? The LENOX Tools 8-Inch is an ideal 8-inch circular saw blade that is suitable for metal cutting tasks.

The blade is equipped with 50 teeth that help you cut metal faster. It is designed with titanium carbide-tipped material that is resistant to material buildup.

Additionally, this blade offers less burring as compared to other abrasive blades. This means that you will not require secondary grinding. In addition, it prevents materials from burning.

The blade is easy to use and resharpenable if you have the circular saw blade sharpener. It is a quality product that is made in China and provides great results when cutting metal.

SPECIFICATIONS

- Size: 8″Style: 50T Steel

- Material: Carbide

- Cutting Diameter: 8 inches

- Weight: 1 pounds

- Dimension: 9 x 9 x 1 inches

PROS

- The blade is easy to use

- Made with strong material for durability

- Prevents the material from burning

- Resists material build-up

- You can resharpen the blade

CONS

- Some users say it loses some its teeth when cutting

- Doesn’t last well on steel sheet

BOTTOM LINE

When it comes to metal cutting, you need a strong blade that works well without worrying about breaking. The LENOX offers quality cuts and it is designed to last for many years. When the blade gets dull, you can re-sharpen it so you don’t have to buy another blade. This extends its life and you can enjoy using it for many years.

- The product is 8x50 STL Circle Blade

- Easy to use

- The product is manufactured in China

- Titanium Carbide Tipped resists material build up

- Less burring than Abrasive cutting

- Reduced Material Burning

- Triple Chip Grind for added durability

- Resharpena

#4 Diabo By Freud D1060X 10″ X 60 Tooth Fine Finish Saw Blade

Equip your circular saw with the Freud D1060X 10″ blade. This is an incredible blade that provides smooth finishes when you are handling delicate molding and wood. The blade helps you get clean and accurate cuts.

It saves you more time since the cuts you make with this blade do not need sanding. The blade is ideal for carpenters, DIY lovers, and fin cabinet makers among other people who want to achieve smooth crosscuts.

The blade can also handle cutting different materials like melamine, oak, pine, delicate molding, and veneer plywood among others. It provides you with a clean-cutting design and comfortable use.

The teeth of the blade are laser cut to offer easy feed and this helps you achieve more control on the position of the blade. You can get your job done fast in less time.

SPECIFICATIONS

- Size: 10 inch

- Material: carbide

- Measurement System: Metric

- Weight: 1.7 pounds

- Dimension: 13.7 x 11.7 x 0.3 inches

PROS

- The blade stays sharper longer

- It can fit different types of miter saws

- No vibration or noise during operation

- Quality material making it durable

- Offers cutting accuracy and efficient work

CONS

- Complaints of lousy cuts

- It burns the material

BOTTOM LINE

This is a durable blade that is designed to help you achieve precise and smooth cuts on various materials. It is equipped with laser-cut stabilizer vents that minimize noise and vibration. Therefore, you can achieve a relaxed position and gain more control. Also, these features minimize friction as well as warping to lengthen the life of the blade.

- TiCo Hi-Density carbide specifically designed for each application to increase performance

- Perma-SHIELD Non-stick Coating protects from heat, gumming, & corrosion

- Super thin laser cut kerf for fast, durable, and clean cuts

- Made in It

#5 Overpeak 12 Inch Saw Blade 100 Teeth Fine Finish Wood Cutting Circular Saw Blades

When it comes to picking the right blade for your circular saw, it is important to consider the blade quality. You want a blade that will provide you with an incredible cutting performance without compromising durability. This is exactly what you get from the Overpeak 12 Inch Saw Blade.

The blade is designed with a tougher tungsten carbide that is 5 times durable as compared to other circular saw blades. The blade has a thin kerf and this results in fast and smooth cutting with minimal material wastage.

You can use it on various machines like miter saws, table saws, and circular saws enjoying a cutting speed of up to 5000 rpm. The blade features low noise when cutting.

Additionally, it is equipped with 5 laser-cut expansion slots and a laser-cut stabilizer vent to trap vibration and noise during operation.

SPECIFICATIONS

- Size: 12”-100T

- Material: Carbide

- Weight: 2.9 pounds

- Dimensions: 15.4 x 13.2 x 0.4 inches

PROS

- Has a thin kerf for smooth cutting

- The most durable blade

- Works well on different types of saws

- Provides accurate and smooth cuts

- No noise or vibrations during work

CONS

- Doesn’t have direction arrow

- The blade feels heavier

BOTTOM LINE

If you are looking for a durable circular saw blade, this can be a great purchase. The blade features a strong and durable construction which makes it tougher than other circular saw blades. It is also suitable for use in different saws which makes it versatile. On top of that, you will enjoy a great cutting experience because it has a unique tooth design to offer you straight and smooth cuts.

- ▲Material - OVERPEAK saw blades made of tougher tungsten carbide for up to 5x longer cutting life than other saw blades

- ▲Low Noise & Cutting Stable - 6 Laser cut expansion slots and 4 Laser-cut stabilizer vents trap noise and vibration, keeping it cool and reducing blade warp

- ▲Alternate-Top Bevel Teeth - The 10 inch saw blade with unique tooth design provides straight cuts and cutting smoother

- ▲Machine Use - Framing saw blade is great for circular saw, table saw, miter saw. RPM up to 6000

- ▲General Usage - The Overpeak 10 inch carbide blade is 90 tooth and suitable for ripping wood, crosscuts wood, plywood, and lamin

#6 Irwin Tools Metal-Cutting Circular Saw Blade

If you are looking for the best 7 1/4 circular saw blade, get the IRWIN and you will love working with the blade. This 7-inch metal cutting blade features anti-vibration vents that cool the blade to provide you with smooth and accurate cuts.

The blade is best suited for cutting hard materials like thin steel and ferrous steel. It is equipped with 48 teeth that offer the best cutting experience. The blade is designed with strong teeth that can handle impact for a long time.

This reduces wear and you will enjoy many years of cutting with this blade. It also features an anti-kickback tooth shoulder that helps you achieve consistent cutting results.

Besides, the blade is stable enough to help you get accurate and smooth cuts. This makes it suitable for professional metal cutting tasks.

SPECIFICATIONS

- Size: 7-1/4″ 48T

- Style: Metal Cutting

- Material: Carbide

- Weight: 12 ounces

- Dimension: 8.7 x 8 x 0.6 inches

- Measurement System: Metric

PROS

- It provides fast and smooth cuts

- The blade is designed to last longer

- Nice kickback design to reduce dust sparks

- Offers professional wood cutting results

- The blade offers clean cuts

CONS

- Many users complain about its durability

BOTTOM LINE

When it comes to metal cutting, not any blade can give you the best performance. You need to get the best 7 1/4 circular saw blades that are best suited for metal cutting like the IRWIN model. This blade provides you with better control so that you can achieve smooth and precise cuts. It is also designed with strong carbide teeth that make it durable to offer you with long life.

- Laser cut blade

- Anti-vibration vents prevent wobble for straighter, truer cuts

- Metal cutting grade carbide teeth stay sharp for long-lasting durability

- Anti-kickback tooth shoulder for safer cutting

- Ideal for cutting thin st

#7 Oshlun SBF-080048 8-Inch 48 Tooth TCG Saw Blade

Maybe you have checked several metals cutting circular saw blade reviews and you haven’t found the right one. You can consider the Oshlun SBF-080048 for your metal cutting tasks.

This blade is suitable for steel and ferrous metal and it fits Milwaukee and other 8-1/4 inch saws. It brags of quality triple tooth chip tooth grind that makes it ideal to handle any ferrous metal cutting tasks.

Therefore, you can depend on the blade when you are cutting steed studs, pipe, iron, flat stock, and channel among others. On top of that, you can use the blade to cut non-ferrous metals such as brass, aluminum, and copper.

The presence of C-6 micro grain carbide that features titanium offers a durable life and provides burr-free cuts without sparks.

SPECIFICATIONS

- Material: Carbide

- Weight: 8 ounces

- Dimension: 10 x 9.5 x 0.5 inches

- Cutting Diameter: 8 inches

PROS

- Does a great job in cutting metal

- Provides a cutting speed of 5,800 rpm

- The blade is designed to last longer

- It provides faster cuts than other blades

- Works well with ferrous and non-ferrous materials

CONS

- Users complain about blade performance and durability

BOTTOM LINE

This is one of the most durable metal cutting blades that provide 5-10 times faster cuts than other blades. It also provides 30 times a long time as compared to other abrasives. Therefore, you will experience fewer blade changes. It also features laser-cut expansion slots that help you achieve accurate cuts.

- Fits: Milwaukee and 8-1/4-Inch Saws

- Max RPM: 5,800

- Professional Grade C-6 Carbide

- Laser Cut Expansion Slots

- Triple Chip Tooth Gr

BEST CIRCULAR SAW BLADES BUYER’S GUIDE: THE CORE FACTORS TO CONSIDER

If you are a tradesman or a handyman, you need the most reliable circular saw blade in your toolbox, truck, or shop. It is a very important tool to deal with all your cutting needs. Are you in the market for a high-quality saw blade? Here are the factors to consider before you buy a blade for your saw.

APPLICATION

This is perhaps the most crucial factor when it comes to buying circular blades. First, you need to know the type of saw you have then understand what material you are supposed to cut. There are different types of circular saw blades.

Each type is only suitable for a particular use. There are wood, masonry, metal, and plastic cutting blades. We also have general-purpose circular blades that can cut through different types of materials and are not optimized for a particular use.

When you have something to cut, you have to choose the right saw blade to get the job done as quickly and as efficiently as possible.

NUMBER OF TEETH

The cutting action of a blade depends on the number of teeth it has. If a blade has more teeth, it will give you a smoother cut. Fewer teeth result in a rough finish because the blade cuts bigger chunks of material. If you want smoother cuts, you can choose the crosscut blade; otherwise, you can go for rip blades.

GULLET

The gullet is the space between blade teeth. Different blades have different gullets. A narrow gullet produces smaller chips resulting in a smoother cut while a wider gullet results in rough cuts because it produces bigger chips.

TOOTH CONFIGURATION

The way the teeth on a blade are configured determines how the blade performs. Blade teeth get configured for ripping, crosscutting, and cutting through specific materials such as MDF, laminates, etc.

Common tooth configurations include Alternative Top Bevel (for crosscutting), Flat Top (for ripping), and Combination Tooth (for general purpose use). Choose a tooth configuration that works best for the job you have at hand.

TOOTH ANGLE

Also referred to as the hook, the tooth angle is the angle between the blade tooth and the blade centerline. The tooth angle can either be positive or negative. Blades with higher positive hook angles are more aggressive than those with lower hook angles.

BLADE QUALITY

The quality of a blade depends on the material used to make it. High-quality blades work well even when used to cut through steel or carbide. The blades are durable, and their teeth can get resharpened over and over again. The best blades are thin to produce a more economical kerf size.

HOW TO USE BEST CIRCULAR SAW BLADES

Before you start using your circular saw, you need to prepare the workspace. The piece to be cut needs clamping, and you may also want to use a sawhorse and a rigid foam. Once you set up your workspace, you can follow the below steps.

CHOOSING THE BLADE TO USE

As stated earlier, blades come in different sizes. If you need a finer cut, choose a blade with more teeth. That applies to all power tools that you use. If you want to cut metal, plastic, or wood, ensure you purchase the type of blade that’s meant for that purpose.

ADJUST THE DEPTH OF THE CIRCULAR SAW BLADE

There’s a nob at the back of your saw. You can use it to adjust the depth of your blade. The blade should not be more than a quarter-inch below the bottom of the material you want to cut. This will provide you with enough clearance for cutting. It also helps in preserving the sharpness of the blade and is safer.

START CUTTING FAR FROM THE EDGE

Just before you cut, set the blade to run to its full speed. This reduces kickbacks and makes the cuts to be cleaner. However, before turning on the saw, ensure the blade is in line with the part you want to cut. It’s best to have a saw with a laser guide.

MAKING THE CUT

When cutting the material, remember to take into consideration the thickness of the blade (its kerf). If you cut directly on top of the line, you might eat into your measurement.

Cut it such that the measurement line remains untouched. Once you’ve turned on the saw, place it where you want to cut and push it forward. Try to be as steady as possible to get a perfect cut.

CIRCULAR SAW BLADES CUTTING TECHNIQUES AND HIDDEN TIPS

It’s good to learn how to use circular saw effectively and professionally. These techniques and tips will come in handy, no matter the project you are handling.

USE PROPER DEPTH FOR THE BLADE

Don’t set the blade to go so deep. This can cause some problems for you. Wrong blade depth can be dangerous because a large portion of the blade will get exposed as you cut. The saw will be more likely to kick back and bind. Besides safety issues, blades also cut better and efficiently when set properly.

BLADE DEPTH IS SET BEFORE CUTTING

Do not start cutting before you set the blade depth. To set it, unplug the saw then hold it alongside the board. The blade guard should be retracted during the setting. Use the depth adjusting knob or lever and pivot the base of the saw. Adjust the blade depth until it is about a quarter or half an inch below the board. You can then tighten the knob or lever.

AVOID BINDING

You should allow the part you cut to fall freely. But you should remember that when cutting wood, the falling part can go with some part of the wood. To avoid this, you can carefully support the part that’s expected to fall so that it doesn’t chip off some wood parts. However, you should not restrict, hold tightly, or clamp the piece to be cut off.

SUPPORT PLYWOOD WHILE CUTTING

When you are crosscutting plywood, you need to support its entire length. Without doing that, the plywood veneer can splinter or tear as the piece you cut off drops. The saw can also bind.

DON’T SUPPORT THE MATERIAL TO BE CUT ON BOTH SIDES AND ENDS

If you support both sides of the material being cut, a kickback problem will arise. As you near the end of the cutting, the material will bow downwards. This will pinch the blade and cause the material you are cutting and or the saw to buck. This is very dangerous.

ANGLE CUTTING TECHNIQUE

Circular saws come with blade guards that need to be retracted when you cut at an angle. Before you start cutting, ensure you retract the guards. Once you start cutting, you can release the guards. The guards tend to catch the material being cut, which can result in cutting mistakes.

SAFETY TIPS FOR USING THE BEST CIRCULAR SAW BLADES

Circular saws are very dangerous if not properly used. That’s why only trained technicians must handle them. But even for trained technicians, some precautions must be observed. Here are some of the safety tips for using circular saws.

SAFETY GEAR

Don’t set the blade to go so deep. This can cause some problems for you. Wrong blade depth can be dangerous because a large portion of the blade will get exposed as you cut. The saw will be more likely to kick back and bind. Besides safety issues, blades also cut better and efficiently when set properly.

DEPTH OF CUT

As had been mentioned earlier, set an appropriate depth of cut before you start cutting.

BLADE GUARDS

Retract the blade guard manually to prevent it from getting caught.

AVOID FREE-HAND CUTTING

Circular saws are light, so some technicians make the mistake of using them to cut materials they hold in their hands. This has led to man accidents. Any material to be cut should be supported on the right bench.

USE A CIRCULAR SAW FOR ITS INTENDED PURPOSE

Don’t use a circular saw or a blade for a task for which it wasn’t intended. There are blades for cutting metal, wood, or plastic. Ensure you use the correct blade for whatever you want to cut.

CUT SAFELY

Before you begin cutting, ensure the saw is working properly. Using a faulty saw can be dangerous. Also, ensure the material to be cut is appropriately supported so it cannot slip and cause an accident.

TIPS TO MAINTAIN YOUR CIRCULAR SAW BLADES

Like any other tools or equipment, circular saw blades need to be taken good care of so they can serve you longer. Here are some tips for maintaining your circular saw blades.

PROPER STORAGE

Proper storage is necessary to maintain the blade’s quality. If you have any blades, you should avoid storing them where they can knock each other or on any other surface that can destroy them. This will prevent them from getting scratched or dented.

KEEP THEM DRY

Since circular blades are made of metal, they will corrode, pit, or rust when exposed to moisture. This will eat into their surface and make them weaker. If you continuously expose your blades to moisture, they’ll eventually become unusable.

AVOID EXPOSING THEM TO VERY HIGH TEMPERATURES

If you expose your blades to very high temperatures, they may crack. Cracks are dangerous because they can throw fragments off, and this can cause injuries.

CLEAN THE BLADES PROPERLY

Proper cleaning is the best way to prevent the blades from corroding or rusting. You need to use a proper cleaning method to remove all the debris that might get deposited on the surface of the blades.

You can use a brass or nylon brush together with some appropriate cleaning agents such as Formula 409, ammonia, or WD-40. Proper cleaning increases the life span of your blades.

PUT THE BLADES ON THE RIGHT SURFACE

Once in a while, you may want to exchange your blades. Where you put the blade, you’ve just removed matters a lot. Placing the blade on metal or cement surfaces may cause some parts of the blade to chip off.

If the chipping occurs at the teeth, the blade can become blunt. Always have a comfortable surface where you can keep the blades before taking them to your store.

FREQUENTLY ASKED QUESTION (FAQS)

Q: DO CIRCULAR SAW BLADES NEED TO HAVE MORE TEETH TO PERFORM WELL?

A: The choice of the number of teeth depends on the nature of the cut you want to achieve. More teeth result in smoother cuts, while few teeth make the cutting process faster.

Q: WHAT STEEL IS USED FOR MAKING CIRCULAR SAW BLADES?

A: There are different types of circular saw blades that are made from various steel types. The type of steel used to manufacture a blade depends on the intended use of the blade. We have high carbon, high chrome steel, etc. used in blade manufacture.

Q: CAN YOU SHARPEN YOUR CIRCULAR SAW BLADES?

A: Yes. You can use a file to sharpen your circular saw blades with steel teeth. However, blades with carbide-tipped teeth need to be sharpened by professionals. Carbide is very hard, and it needs a diamond sharpener.

These blades are also complicated and trying to sharpen them on your own may end up damaging them. High-quality blades can be sharpened over and over without losing their efficiency.

Q: HOW MANY AMPS DOES A CIRCULAR SAW USE?

A: Many circular saws use 15 amperes. You can check your saw’s fact sheet to get the value of the amps your saw uses. 15 amps rating is safe for home use, and it corresponds with 1,440 watts which is also a safe power rating.

FINAL VERDICT

The type of circular saw blade that you have affects the overall performance of your tool. I have provided you with reviews of the best circular saw blades that will be great in your circular saw. I selected quality and durable blades that can cut metal and other materials perfectly.

I have also provided you with important tips that will help you pick the right blade that suits your needs. I hope after going through the reviews and guide, it will be easy for you to determine which of the above blades works well for your tool.

Table of Contents