Drill presses are typically used in metalworking, woodworking, and plastic working. In metalworking, drill presses are used to drill sheet metal holes and create holes in metal parts for assembly.

In woodworking, drill presses are used to drill holes in wood for screws dowels or to create mortises and tenons. In plastic working, drill presses drill holes in plastic parts for assembly.

In this article, we will talk about what is a drill press used for in woodworking. So, without any further ado let get’s started.

What is A Drill Press Used for in Woodworking and Carpentry Shop? What It is and How Do You Use It?

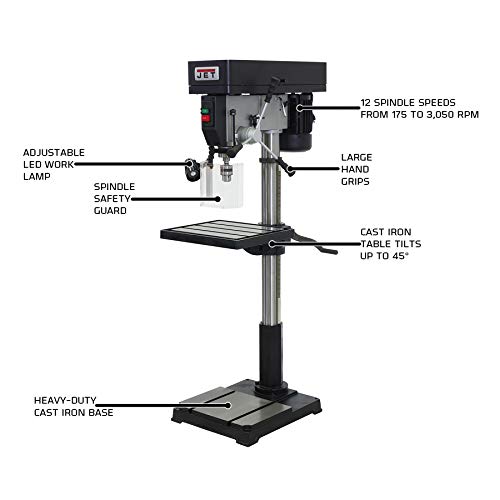

There are many different drill presses, but all have a few essential components: a base, a column, ahead, a table, and a spindle. The base is the part of the drill press that rests on the floor or workbench.

The column is the part of the drill press that extends up from the base. The head is the part of the drill press that holds the drill bit.

The table is the part of the drill press that the workpiece rests on. The spindle is the part of the drill press that the drill bit is attached to.

Drill presses can be powered by an electric motor or a compressed air motor. Electric drill presses are the most common type of drill press.

A standard household electrical outlet powers them. Compressed air drill presses are powered by compressed air, typically supplied by an air compressor.

What is a Drill Press?

Drill presses are typically used to drill metal, wood, or plastic holes. A drill press is a machine that uses a rotating spindle to drill holes in a workpiece.

The workpiece is held against a stationary table, and the spindle is moved up and down to create the desired depth of the hole.

- variable-speed: 1-1/2 hp motor has 12 speeds from 175 to 3,050 rpm.

- repetition: 1/2-diameter external depth stop, with three-nut locking feature, allows for fast adjustments.

- accuracy: depth stop has a quick-set bolt for fast, accurate adjustments.

- visibility: built-in led worklight provides additional visibility.

- versatility: quick-release crank-operated worktable can tilt +/- 45°.

- Horsepower: 1.5

- Included components: Drill Press, Table, Base, Column

- Power source type: Corded Electric

How Does a Drill Press Work?

Every drill press consists of a base, column, and head. The head contains the drill chuck, which holds the drill bit, and the motor. The column is adjustable and can be raised or lowered to position the workpiece.

The base is adjustable and can be tilted to position the workpiece. Most of the drill press is typically used to drill metal, plastic, or wood holes.

The drill chuck is mounted on the end of the spindle, which is driven by the motor. The motor is connected to the drill chuck by a belt or gearbox.

The belt or gearbox transfers power from the motor to the spindle. The speed of the drill press spindle can be controlled by changing the belt or gear ratio.

The column is adjustable and can be raised or lowered to position the workpiece. The base is adjustable and can be tilted to position the workpiece.

The workpiece is secured to the table mounted on the base. The table can be moved in both directions to position the workpiece.

You will find the drill bit is inserted into the drill chuck. The workpiece is positioned under the drill bit.

The drill press is turned on, and the drill bit is lowered into the workpiece. The drill bit is then moved up and down to drill the hole.

There are many uses for drill presses. Some of these include:

Drilling holes in various materials

- Cutting threads

- Boring holes

- Reaming holes

- Counterboring

- Tapping holes

- -Shaping metal

- Smoothing wood

- And many more!

Type of Drill Press

There are several types of drill presses on the market, but they all have one common goal: to drill holes in various materials.

The most popular type of drill press is the benchtop drill press. It is small and portable, making it perfect for the home workshop.

The floor-standing drill press is the most significant and most potent type. It is perfect for industrial applications where much drilling needs to be done.

It is also the most expensive type of drill press.

The radial arm drill press is a specialty drill press that can drill angled holes. This type of drill press is perfect for drilling holes in door hinges.

Drill presses come in a variety of sizes and power ratings. It is essential to choose the perfect drill press for your needs. If you are a home hobbyist, a benchtop drill press is a perfect choice.

So, what is the best drill press for you? The answer to that question depends on your needs and budget. The benchtop drill press is an excellent choice for a home hobbyist.

If you need a drill press to handle large industrial applications, the floor-standing drill press is the best option.

Size of Drill Press

Are you looking for a drill press that’s just the right size for your workshop? Not sure where to start? This article is for you!

The size of the drill press is an important consideration when purchasing this type of equipment.

Drill presses come in various sizes, with the smallest being about 10″ in diameter and the most prominent being around 30″.

The size of the drill press you choose will depend on the projects you plan to work on. If you need a drill press that’s capable of handling large projects, you’ll need to go with a model that’s at least 20″ in diameter.

If you’re only going to use your drill press for smaller projects, a model that’s 10″ in diameter or less should work just fine.

Another factor to consider when choosing a drill press is the power rating.

Drill presses come in various power ratings, with the smallest being around 1/3 horsepower and the largest being around 3 horsepower.

The power rating of the drill press is vital because it determines the size of the drill bit that is used with the machine.

If you need to use a significant drill bit, you’ll need a drill press with a high-power rating.

Drill Press Power

The drill press power is measured in watts. The higher the wattage, the more influential the tool.

Most benchtop drill presses have a wattage of around 500 to 600 watts. This is more than enough power for most drilling applications.

Floor-model drill presses typically have a wattage of 1,000 or more. This is more than enough power to drill through most materials.

However, if you plan to do a lot of drilling in more challenging materials, such as metal, you should consider a model with a higher wattage.

If you are in the market for a new drill press, be sure to consider the wattage. It is an essential factor to consider when making your purchase.

Drill Press Speed

The speed of a drill press is an important consideration when choosing this tool for your shop.

Many factors affect drill press speed, including the size and type of motor, the gear ratio, and the weight and size of the workpiece.

The size of the motor is the most crucial factor in determining drill press speed. Larger motors can rotate the drill chuck faster than smaller motors.

The gear ratio also affects drill press speed. A higher gear ratio means that the chuck will rotate more times for each revolution of the motor.

This means that the drill chuck will rotate slower, but the drill will produce more torque.

A lower gear ratio means that the chuck will rotate more times for each revolution of the motor.

This means that the drill chuck will rotate at a higher speed, but the drill will produce less torque.

The weight and size of the workpiece also affect drill press speed. Heavier workpieces require more torque so that the drill chuck will rotate at a slower speed.

Larger workpieces require more space around the drill chuck, so the drill press must have a larger table to accommodate them.

Features of a Drill Press

The features of a drill press include a base, column, head, table, and drill chuck. The base is mounted to the floor or workbench, the column is mounted to the base, and the head is mounted to the column.

The head contains the drill chuck, which holds the drill bit, and the table is mounted to the head.

The drill chuck is mounted to the end of the spindle, which is rotated by a motor. You will see the drill bit is inserted into the drill chuck, and the motor is turned on. The drill bit then rotates and drills a hole in the workpiece.

The column is mounted to the base to be raised and lowered. This allows the height of the table to be adjusted to the desired position.

The column is also mounted to the base to be rotated. This allows the drill chuck to be rotated to the desired position.

The head is mounted to the column to be moved left and right. This allows the drill chuck to be moved to the desired position.

The table is mounted to the head to be moved up and down. This allows the workpiece to be positioned at the desired height.

The table is also mounted to the head to be rotated. This allows the workpiece to be rotated to the desired position.

The drill chuck is keyless mounted to the end of the spindle. It holds the drill bit to be inserted into the workpiece.

The drill chuck has several settings that can be adjusted to fit the size of the drill bit.

The drill chuck is also adjustable to be tightened or loosened. This allows the drill bit to be tightened or loosened.

The motor is a rotary motor that is used to rotate the spindle. The motor is mounted to the base so that it can be rotated. This allows the spindle to be rotated to the desired position.

The motor is also mounted to the head to be moved left and right. This allows the spindle to be moved to the desired position.

Uses for a Drill Press

A drill press can be a valuable tool for various projects. It can create holes in metal, wood, plastic, and other materials.

Depending on the project, it can be used to create straight or angled holes.

One common use for a drill press is to drill holes in metal. This is useful for various reasons, such as creating a hole for a bolt or screw or creating a hole for a metal bracket. A drill press can create straight or angled holes in metal.

Another everyday use for a drill press is to drill holes in wood. A drill press can create straight or angled holes in wood.

A drill press can also create holes in other materials, such as plastic or tile. It can also create holes in thinner materials, such as sheet metal.

Frequently Asked Question (FAQs)

What Can I Do with A Drill Press?

There are many things you can do with a drill press. You can use it to drill holes in wood, metal, and other materials. You can also use it to sand and polish materials.

Is It Worth Buying a Drill Press?

There is no easy answer to this question as it depends on various factors, including what purpose you will be using the drill press for and your budget.

That said, a drill press can be a helpful tool for various projects and can be worth the investment.

For basic DIY projects, a hand drill may be all you need. However, a drill press can be a valuable tool for more complex projects or if you need more precision.

Drill presses are especially useful for drilling holes in metal or wood or for sanding or buffing. They can also be used for routing and mortising.

The price of a drill press can vary depending on the size and features of the model, but generally, they are affordable.

If you are unsure if a drill press is a suitable tool for you, it may be worth renting one to test it out before purchasing.

Can You Carve Wood with A Drill Press?

Yes, you can carve wood with a drill press. Drill presses are often used to carve wood to create accurate and consistent cuts.

When carving wood with a drill press, it is vital to use a sharp bit and keep the drill press’s speed low.

You should avoid putting too much extra pressure on the bit of the drill press, as this can cause the wood to break.

If you are new to carving wood with a drill press, it may be helpful for you to practice on a piece of scrap wood before trying to carve a more intricate design.

Can You Use a Drill Press for Mortising?

Yes, you can use a drill press for mortising. A drill press can be an excellent tool for mortising because it is adjustable and has a chisel held in place by a chuck.

When mortising with a drill press, you will want to adjust the depth of the drill bit so that it is just below the surface of the wood.

You will also want to use a slower speed to don’t create too much heat and damage the wood.

To use the drill press for mortising, you will first want to drill a hole in the middle of the wood the same size as the mortise. Then, you will use the chisel on the drill press to create the mortise.

Can You Sand with A Drill Press?

Yes, you can sand with a drill press. The drill press can create a smooth surface on wood or metal.

The drill press can create a smooth surface on both wood and metal. The drill press can be used to sand down small pieces of wood or metal, or it can be used to create a flat surface on a larger piece of wood or metal.

The drill press is a great tool for sanding because it provides a lot of pressure and consistent speed. This makes it easy to create a smooth surface on your wood or metal.

If you are looking to create a smooth surface on your wood or metal, then the drill press is the tool for you. It is easy to use and provides a lot of pressure and consistency.

- INFINITELY VARIABLE SPEED: Mechanical variable speed (250 to 3,000 RPM) with no belt changes.

- PINPOINT POSITIONING: Laser guides provide an accurate indication for tool point.

- ADDED STABILITY: Oversize cast iron base.

- COMFORTABLE WORK CONDITIONS: Reversible handles can be mounted on either side of the machine.

- RAPID ALIGNMENT OF STOCK: Adjustable fence system provides a perfect 90-degree relationship to the table.

Conclusion

A drill press offers high precision when drilling holes, making it a valuable tool for woodworkers and other DIYers.

Drill presses are also versatile, capable of performing other tasks such as deburring, reaming, and tapping.

With the right bits, a drill press can be used for various drilling applications.

Although drill presses are more expensive than regular drills, they can save time, and if you are looking to buy a tool that can help you achieve precision results, then a drill press is a tool for you.

It is an excellent investment for any woodworker or DIY enthusiast. It offers precision and uniformity that is unmatched by regular handheld drills.

Not only is it great for drilling holes, but it can also be used for deburring, reaming, and tapping.

You May Also Interested to Read:

1. What Are Band Saws Used For and The Different Types Of Band Saws

2. What Are The Uses Of Reciprocating Saws With Its Different Types, Pros, And Cons

3. What Are Scroll Saws Used For and Types of Scroll Saws with Its Structure, Workload, Pros, and Cons

4. How to Cut Plexiglass with a Circular Saw -Expert DIY Guide

5. How to Cut Plexiglass with Dremel – Cutting Plexiglass with Dremel

To Learn More About Woodworking and Carpentry Visit at iSaw Guide Home

Table of Contents