Have you got a good quality hand saw that you’ve been using for quite some time? It’s come to a stage where sharpening is the only option, but you don’t know how to sharpen a hand saw blade.

Well, there’s no need to fret, because this article has got you fully covered on all the aspects that you need to know to sharpen a hand saw at home or at your workshop yourself.

There are many ways to sharpen a hand saw blade. From ‘hand saw teeth guide‘ to ‘hand saw sharpening kit‘, with this guide sharpening your hand saw will never have been made easier.

Before knowing how to sharpen your hand saw, you’ll first need to know your tool’s basics for you to understand the steps to sharpen a hand saw adequately.

13 Different Types Of Hand Saws For Woodworking And Carpentry Shop

1. Hack Hand Saw

Having a thin blade of 18 to 32 Teeth per Inch (we’ll discuss this term later in the article), the hack hand saw was initially used to cut metal. But with time, it is also became used to cut other thin materials such as plastic.

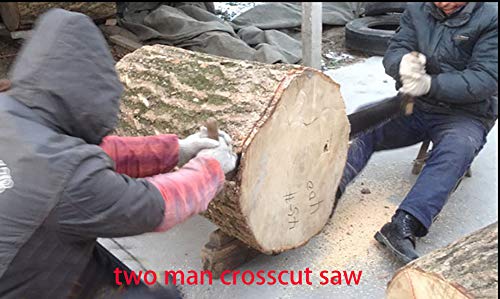

2. Crosscut Hand Saw

A cross-cut usually has an 8 to 12 Teeth per Inch (TPI) blade and makes rough cuts in wood.

3. Bow Cut Hand Saw

A bow cut saw is an upgraded version of a cross-cut saw. It is a hand saw for trees and is commonly used for pruning trees and cutting logs, while also making carved cuts. Its blade usually consists of 3 to 8 TPI.

4. Coping Hand Saw

The coping hand saw is a lightweight hand saw for wood, has 15 to 17 TPI blade,s and is ideally used for carved woodcuts.

5. Fret Hand Saw

The fret saw has a blade of an approximate value of 32 TPI, giving it great accuracy in its work. It is used for latticework producing curved cuts.

6. Keyhole Hand Saw

Because of their blade having a dagger-like shape, they are known as ‘Jab Saw’. A keyhole saw usually has 7 to 10 TPI and is used to cut irregular patterns out or make small holes using maneuvering cuts.

7. Japanese Hand Saw

Depending on the type of Japanese saw, these saws’ blades consist of 9 to 25 TPI. These saws use a pull motion for cutting instead of a push motion, resulting in exact and clean cuts.

8. Rip-Cut Hand Saw

One of the most commonly used saws as it can perform several jobs. Unlike the other saws, it has a low TPI of about 4 to 6, but each tooth is sharp enough to carry out the cuts quickly.

9. Back Hand Saw

It is also known as the ‘Dovetail Saw’ and has a TPI blade of 15 to 20, making it ideal for exact cuts with precision and accuracy. These benefited from their large handle and steel or brass metal piece attached to the blade’s opposite side, allowing less force to be exerted while cutting.

10. Pruning Hand Saw

They have a long curved blade and slanted handle, with a TPI of 5 to 12, making them the perfect hand saw for gardening, cutting shrubs, and pruning trees.

11. Veneer Hand Saw

These saws have a double-sided, short, 13 TPI blade suitable for cutting hardwood veneers, laminates and plastic.

12. Camping Hand Saw

As the name suggests, it is used for camping because of its folding feature, lightweight and portability. Its blade consists of 6 to 8 TPI

13. Bone Hand Saw

This saw is used for the sole purpose of butchery and cutting bones. It has a stainless steel blade of 7 to 10 TPI that will not rust with animal/human blood contact, making it the perfect saw for this use.

2 Types of Hand Saw Teeth Guide

The following set of teeth is most common on all hand saws.

1. Cross-cut Teeth

These teeth are pointing straight up, and the leading edge (front) of the teeth is beveled. In other words, they are angled on the inside edge as well as the outer edge. To make it easier, think of these sets of teeth as knives. These teeth are used to cut against the grain of the wood.

2. Rip cut Teeth

On the other hand, the rip cut teeth are used to cut along the grain; hence, much work is not required compared to when using a cross-cut saw. These teeth are pointing towards the side, the leading edge is straight, and they are not angled on the inside edge. The outer edge, however, is angled. This set of teeth is like chisels, and hence are square-shaped.

Teeth Per Inch (TPI) Vs Points Per Inch (PPI)

While sharpening your hand saw, it is essential to know the TPI and PPI of the saw. Above all, to detect this, you must first understand the difference between TPI and PPI.

TPI refers to Teeth per Inch. The whole tooth is counted as a whole, including both edges. The two edges; outer and inner, make an entire tooth and are counted as one tooth. The numbers of teeth are counted that are present in 1 inch; this value gives you the Teeth per Inch.

Whereas PPI, which refers to points per inch, is a measure of only the teeth’ peaks, points, and NOT the full tooth itself, including the outer and inner edge.

In most cases, the TPI of a saw is less than the PPI of it.

Comparison Between Traditional Hand Saw Vs Store Hand Saw

A tip to keep in mind, and this answers a question that you may have in mind ‘is it worth sharpening a hand saw‘. Traditional hand saw’s blade or plates are made from softer steel that can easily be sharpened using a file by reducing the metal off of them very nicely.

Hence keeping the file proper and also getting the job done. On the other side, nowadays store-bought hand saws have had their teeth hardened. Hardened teeth make it hard for a standard file to sharpen the teeth, consequently ruining the file.

You can check the hardened teeth by seeing the color of the blade. Traditional hand saw’s plates will have a uniform color; whereas store hand saws will have the tip of their teeth another color compared to the rest of the plate, indicating that they have been hardened.

So, in short, it is worth sharpening an old hand saw, because you’ll know that it is a traditional hand saw.

Essential Hand Saw Sharpening File Kit

When your hand saw becomes dull, you’ll need to sharpen it. There are many hand saw sharpening file kits in the market. The best hand saw sharpening files are in the kits of the Bahco saw sharpening files, or the Grobet hand saw files that consist of the essential 6pc sharpening files.

In most file kits you should make sure that you have a mill file for an evening out the teeth on the saw. A cross-cut file, a 3 square file for crosscut saws, and a tapered file for the sharpening of a rip hand saw.

Apart from this, you’ll need a Saw File Holder with an angle indicator on it, or more likely known as the ‘Angle Gauge’. This accessory will prove very beneficial during the sharpening of a hand saw.

Also, it is best to purchase files that already have handles on them. If they don’t, then you can buy them separately and add them to yourself.

Filing Movements

Filing the teeth of the saw requires some techniques. These movements ensure that the teeth of the saw remain undamaged and are sharpened to the highest accuracy.

Slope

This movement has the ends of the file, namely the end part and handle part of the file, moved vertically up or vertically down to give it some slope during sharpening.

Fleam

Fleam is opposite to slope because the ends of the file are moved horizontally on its axis, rather than vertically, giving ‘fleam’ to the teeth.

Rake

The last most important movement is the rake, in which the file, at point of contact with teeth, is moved or rolled forward or backward, depending on the saw and the type of teeth.

We’ll discuss further which movements are required at what point of sharpening the hand saws.

Safety Precautions For Sharpening The Hand Saw Blade

Since we’re dealing with sharp objects, safety wear is a must, including long safety gloves and eye goggles to protect your hands and eyes respectively. Secondly, make sure that you clamp the saw or appropriately fix it to avoid any movement of the saw during its sharpening.

Tools For Sharpening Hand Saws

- Hand saw sharpening vise

- Hand saw sharpening files that are suitable for the saw blade

- Angle Gauge

Step By Step Guide On How To Sharpen A Hand Saw Blade

1. Wear Safety Gloves And Goggles

Wearing the necessary safety apparel is the most prioritized step. Please do not proceed further without following this step.

2. Use A Saw Vise for Setting The Teeth And Saw

Take your saw that needs sharpening and joint it in a handsaw sharpening vise. You can buy a vise from the stores readily. They can also be made and customized at home according to your needs. While fixing the hand saw in the vise, make sure that the part of the blade on which the teeth are present faces upwards.

Be sure that only the teeth are exposed, and the rest of the blade is clamped and fixed to prevent any movement during the sharpening of the hand saw blade.

3. Remove Dirt Or Rust First

To prevent the file from being damaged and to ensure the teeth are sharpened correctly, be sure to remove all dirt and rust from the blade, using a liquid blade cleaner that can be purchased from the hardware store.

4. Use A Flat File First To Make The Tops Of The Teeth Blunt And Equal In Height

Before sharpening the teeth, first, use a miler file to even out the saw plate’s teeth points. Use the file across the teeth. Start from the tail to the head, and then vice versa. Check the teeth, observe them visually, if one or two of the tooth are still large in height then run the miler file across them once.

Ensure you do not apply too much pressure on the file or else damaging the teeth will be the consequence.

5. By Looking At The Teeth Take An Appropriate And Corresponding File

By looking at the angle of teeth, the size of teeth, select an appropriate file. Ensure the teeth only come to less than half of the file when it is placed between the teeth gaps or known as the gullet. This will allow the file not to get quickly used up from the inner edge and enable it to have a long life.

For cross-cut saws, it is best to choose a 3 square file or cross-cut file for a cross-cut set of teeth, and a tapered file for rip cut set of teeth.

6. Use Filing Movement To File Cross Cut Saw Teeth

When you have picked the right file for your cross-cut hand saw, you’ll want to achieve a sharp hand saw after you have sharpened it. For that, you’ll need to add a little fleam to your file during sharpening. Check your angle gauge to make sure you do not add too much fleam.

7. Use Filing Movement To File Rip Saw Teeth

The same goes for the rip cut hand saw. During filing, add a little bit of rake to your filing movement. Again, use the angle gauge to check that you are applying just the right amount of rake. Also observe the teeth, to see how much a movement is required for both cases.

(In most cases, the slope isn’t used, but some people use this movement depending on the results they want to achieve. Is it necessary to add any movements? It solely depends on the results you want and how sharp you want the hand saw to be.)

8. File The Teeth

After ticking all these steps, start filing away. Always aim to use 2 to 3 strokes per tooth. For a cross-cut hand saw, you’ll need to file every other tooth, i.e. tooth no.1, tooth no.3, etc. Then turn the saw, and start from the tooth that you missed, and start filing alternative teeth.

For a rip cut, hand saw you can file and sharpen the teeth one by one way. Remember to change sides when one side is completed. For a cross-cut saw, you’ll need to switch sides more than once because of the geometry of its teeth.

9. Check The Saw

The final step, after sharpening your hand saw, is to check its sharpness by doing a test cut. If the saw cuts quickly and swiftly, then you’re good to go, if not then you might want to reconsider giving the set of teeth another stroke of sharpening.

Frequently Asked Questions (FAQ)

Q. How To Sharpen A Handaw At Home?

A. The above-detailed article includes all the information required to sharpen a hand saw at home. The main types of a hand saw are cross-cut saws and rip cut saws, and sharpening process and methods have been mentioned for both.

Q. What Size File is Necessary for Sharpening Saws?

A. People tend to get confused as to what size is needed and whether they might damage their saw if they use the wrong size. There is nothing such as this. When you purchase your hand-saw sharpening file kit, the files will be arranged from small to big or vice versa. Pick the file that you think looks most suitable.

Place it in the gullet between the pair of teeth. Notice the file size compared to the tooth, and whether it’s properly fitted and snuggled in there. The file size should be considerably larger than the teeth to avoid the file wearing out quickly.

Q. How To Sharpen Cross-Cut Hand Saw?

A. Use a cross-cut file or a three triangular file, or whichever you think would suit and fit best for the set of teeth. While stroking the file, use a fleam movement during filing. If you’re a beginner, make sure you have an angle gauge too, to make sure that your file is straight, and you’re adding just the right amount of fleam.

Not too much and not too little. You don’t want to sharpen the teeth over, and you don’t want to leave them dull.

Q. How To Sharpen A Hand Saw With A Dremel?

A. A Dremel is a rotary tool used to sharpen tools. It is also used to sharpen hand saws as well. All the steps are nearly the same. First of all, take all safety measures by wearing goggles and safety gloves. Also, disconnect the power supply of the Dremel tool before use.

Then place your saw to be sharpened in a hand saw sharpening jig. This is similar to a vise only difference is the size. After this, select a suitable diamond cut-off wheel and (if required) a sharpening tool for Dremel for sharpening the set of teeth.

Similar to the steps above, bring the Dremel near the teeth’ gullets and start sharpening as required.

Q. Why Can’t You Sharpen A Hard Point Saw?

A. As discussed before, the hand saws that you get nowadays have their teeth sharpened. These saws are called hard point saws, and the teeth of these saws have been extra hardened compared to the rest of the material. Though sharpening them is possible, it is not advisable as they will completely ruin your hand saw sharpening files.

Q. How To Sharpen Bow Saw Blades?

A. A bow saw is a typical hand saw used mostly for trees. This saw is slightly different from the other saws so its teeth have a different geometry compared to the rest. To sharpen the bow saw, you should use additional files for the diverse set of teeth.

Q. Is It Worth Sharpening Circular Sawblades?

A. Yes, it is, provided that the blade’s teeth have gone dull which prevents the saw from performing its action. If done right, sharpening a circular blade at home can be a handy skill.

Q. How To Sharpen A Backsaw?

A. A backsaw, as discussed, is also known as a dovetail saw. The method for sharpening a backsaw is the same as sharpening a dovetail hand saw. The file for sharpening dovetail hand saws is also the same as those used above. The difference lies in the vise used.

The vise used for a dovetail is smaller, and easily fir between the back metal piece and the set of teeth. Fit the saw in between the vise and clamp it down for further stability.

Conclusion

Written in this article, we have discussed the necessary process for sharpening that you’ll need to know to sharpen your saw blade at home. With all the required information, this article will make your sharpening a saw a piece of cake, whether it’s your first time or you’ve been doing it for ages.

You May Also Interested to Read:

1. How to Sharpen a Table Saw Blade Accurately – A Hands-on DIY Guide

2. How to Sharpen Circular Saw Blades – 7 Steps Handy Guide (2020)

3. How to Sharpen a Pole Saw Blade – 3 Effective Ways (2020)

4. How to Sharpen a Chainsaw with a Grinder – Best Sharpening Method

To Learn More About Woodworking and Carpentry Visit at iSaw Guide Home.

Table of Contents